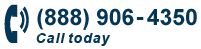

ROPER WHITNEY, 10X16 STRAIGHT CNC FOLDER, MODEL#AB1016E **NEW**

This product is no longer available.

Reference Number: 223

Condition: New

"If you need a machine and don't buy it, then you will ultimately find you have paid for it but don't have it." Henry Ford

Full Product Description

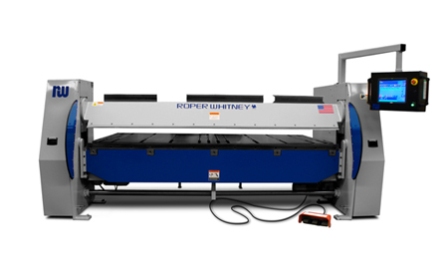

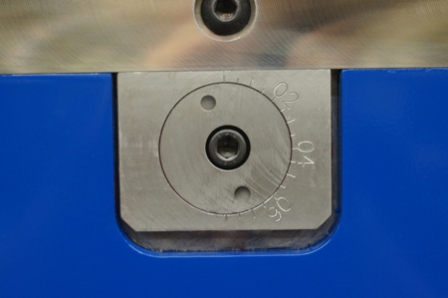

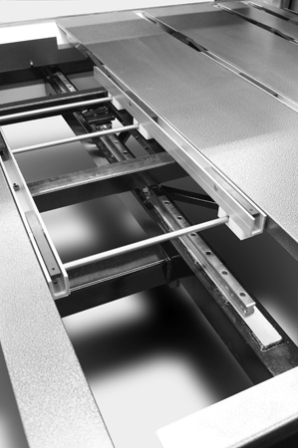

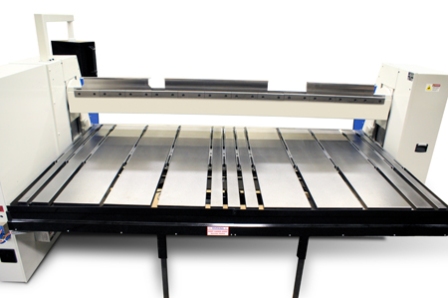

Model: AB1016E Capacity: 16 Gauge (1.5mm) (Mild Steel) Stainless capacity up to 90-degree of 18 gauge (1.2mm) Stainless capacity past 90-degrees of 20 gauge (1.0mm) Bending Length: 122" Backgauge Travel: 40" (1000mm) Working Height: 35" (889mm) Open Height: 4.5" (114mm) Bending Beam Adjustment: 2.0" (50mm) Crowning of folding beam: 5-point 0" to 0.030" Adjustment Electrical: 230 VOLT / 3 PHASE, 60 HZ. Max. Current Draw: 5.5 AMPS Service Required: 15 AMP Wire Gauge For Incoming Power: 14 Gauge Required. Motors: 1.5 HP Clamping Beam 1.5 HP Bending Beam Backgauge motor: 2.5 HP Overall Dimensions: 152.7"L-R X 66.5"F-B System Weight: 6202 lbs. Shipping Weight: 6912 lbs. (A Rotary R3 type Phase Converter is required when connecting to single phase power ) STANDARD TOOLING INCLUDED: (1) .787" X 122" Bending Bar X 122" (1) .390" X .250" Bending Bar X 122" (1) 122" Lower Clamping Jaw (1) 122" Upper Clamping Jaw (30-Degree) Manual crowning of the folding beam is standard on all Autobrakes. A powered crowning system is optional. SYSTEM FEATURES: * Integrated sheet support and material positioning. Workpieces are fully supported by the table beneath the clamping jaw, and automatically positioned to an accuracy of +/- .004" by the computer controlled automatic gauge. * Automatic dual clamping system: No tool change is required to create open, close or tear-drop hems. Open Height can be programmed for ease of part handling. * CONSTRUCTION: Plate and weldment steel construction, delivering superior performance and features in a simplified rigid design. * End housings are a plate-type construction bringing drive components close together for improved stiffness and performance. Actuating mechanisms are secured in rigid mounts at the outside of the housings, allowing easy maintenance. PROGRAMMING FEATURES: * The SYNERGY CONTROL provides greater flexibility to the operator with few keystrokes. * Creation of part programs can be done by text entry in the main operations screen, or part profiles can be drawn and converted into programs. Both part programs and drawings can be stored on the computer's hard drive for future use. PROGRAMMING FUNCTIONS: * Bend Angle * Gauging distance * Offsets for hem operations * Programmable delay for backgauge and gauge fingers for each operation of the program * Open, closed, or teardrop hemming * Open hem height * Clamping force * Jaw opening * Springback compensation * Tool selection - box tool or standard jaw * Radius profile macro * File transfer screen * Customer alph/numeric part number (255 Characters max.) * Information screen for entering of part related data * Material handling instructions * Programmable part counter NOW INCLUDED - NO EXTRA CHARGE .. CROWNING! Provided as standard equipment on the generation "2" Autobrake. This system consists of: * Crowning Cams * Actuating Tool * Interfacing features on bending beam This crowning system provides a quick easy method for adjusting the center crown of the bending tooling to improve accuracy, and adjust the work material straightness when forming radius bends. The system is manually adjusted, and locked in place by the operator. OPTIONAL: * Light curtain - can be mounted to the machine to provide additional protection to the operator during clamping of the work material * Laser scanning system - can be mounted along the lower portion of the machine legs, and scans for interrupts in its sensing field. * 61" Backgauge option 100% MADE IN THE U.S.A.!! INCLUDES 3-YEAR FACTORY WARRANTY!!