1/4" x 6', ATLANTIC, No. HDE BOTTOM-DRIVEN HYDRAULIC **NEW**

Specific Info On This Equipment

This product is no longer available.

Reference Number: 1713

Condition: New

"If you need a machine and don't buy it, then you will ultimately find you have paid for it but don't have it." Henry Ford

Full Product Description

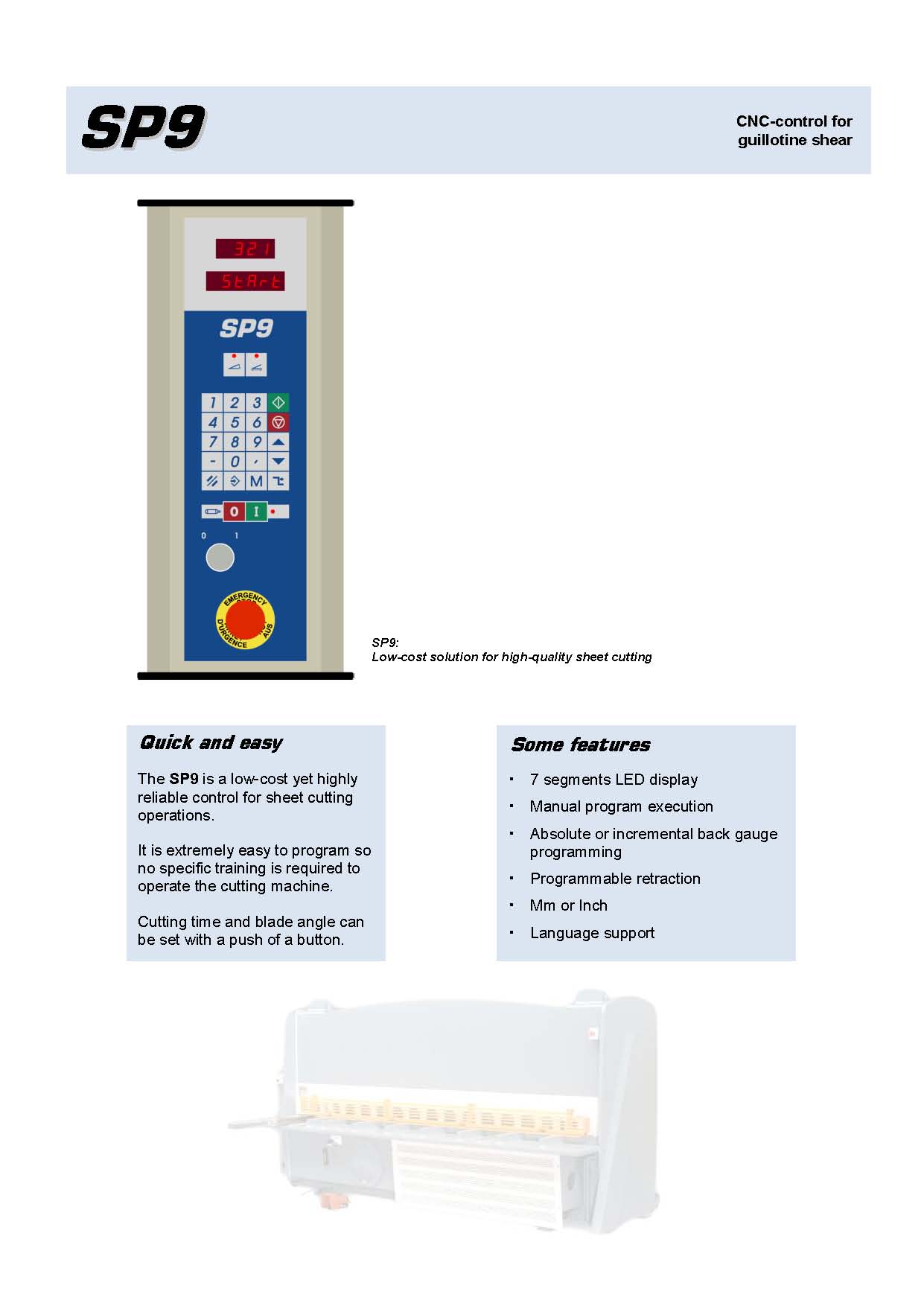

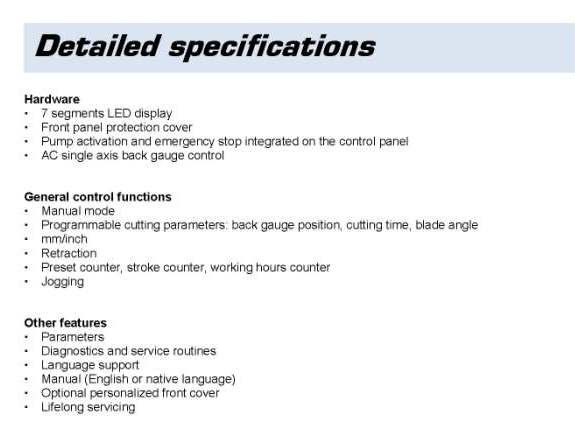

MODEL: HDE 6' X 1/4" CUTTING CAPACITY: 1/4" MILD STEEL, 10 GAUGE STAINLESS CUTTING LENGTH: 80" NUMBER OF HOLDDOWNS: 13 POWER BACK GAUGE RANGE (MOTORIZED): 39" STROKES PER MINUTE: 12-27 SQUARING ARM: 40" ELECTRIC MOTOR: 15 HP VOLTAGE: 220/440VAC OVERALL LENGTH: 106" OVERALL WIDTH: 70" OVERALL HEIGHT: 62" WEIGHT: 7,900 LBS All HDE model shears have the new SP9 control as a standard. The SP9 CNC controls the backgauge and rake angle of the machine. The control also features a programmable retraction of the backgauge and programming mode. Customers who do not like a CNC can still order a machine without CNC upon request The ATLANTIC HDE Shear is a versatile piece of equipment that will give your a competitive edge over your competition. Manufactured on state of the art assembly lines with top quality components, the HDE shear combines quality with affordability. There are several standard features, which contribute to its versatility and will provide your company with safe, accurate, dependable and high productive use, which will put your company ahead of its competition. The HDE Shear is a SAFE machine, built to conform to ANSI B11.4 "American National Standard for machine tools -shears- safety requirements for construction, care and use." The machine comes standard with finger guards, hydraulic overload protection and other safety features. You will find the HDE Shear to be a very VERSATILE machine. The adjustable rake, quick set blade gap adjusters and power back gauge allows the demanding job shop the capability of cutting a wide variety of materials with minimal set up and higher productivity. The machine operates smoothly and quietly with minimal shock or vibration and doesn't require a special foundation. Not only is the machine versatile, safe, but is also DEPENDABLE. The machine is built with top quality components. SPECIFICATIONS & STANDARDS: * Standard motorized backgauge of 39". * Hydraulic sheet hold downs on seperate hydraulic circuit for better pressure control. * Standard 40" squaring arm with scale and tilting front stop. * Very large oil tank. * Cutting capacities rated for steel with 60,000 PSI tensile strength. * Programmable rake angle with the new SP8 control * Quick manual blade clearance setting with leveler * Setup, installation and training by factory trained engineers, nationwide. * 1 Year warranty on parts and labor. CONSTRUCTION * Rugged all steel interlocked and welded construction for max strength and minimum deflection. All frames are stress relieved after welding to provide as near perfect surfaces as possible,which in turn results in better bends. The all- welded construction also resists torque twist that is sometimes found in bolt-together designs. * Low profile. Our underdriven design saves space and doesn't require special foundation. * True guillotine design is guided on hardened ways with roller bearings which virtually eliminate wear. * Full hydraulic series cylinder design. Energy transfers as cut progresses the length of the machine. Hereby you eliminate the torsional forces of the conventional hydraulic design, so there is less strain on the entire machine. * Hydraulic cylinders are manufactured by Atlantic Machine Tools. We use Parker Polypac seals and wipers for our cylinders. * Most hydraulic and electrical components are standard industrial/commercial grade, off-the-shelf items from major manufacturers as Parker, Vickers, Rexroth and Telemecaniquer. * All hydraulics are mounted in the back of the machine under a protective cover, to make it easy accessible. The manifold block brings the valves and hoses together into one compact assembly. *The machine is equipped with 4-edge blades, which means 4 new edges per blade before re-sharpening. OPERATION * Quick set blade gap adjustment at the front of the machine by use of a lever, 3 preset positions. * Power rake angle adjustment (1-3 degrees). This allows us to cut thin material at a smaller angle, minimum twisting of the sheared flanges. * Individual hydraulic holddown cylinders advance independently of the shear blade, securely clamping the worksheet before the ram cycles. The holddowns adjust automatically to varying plate thickness, and are interlocked with the ram to ensure proper clamping before the shearing cycle begins. Soft padded holddowns are available as an option for shearing pre-finished material such as pre-painted, polished aluminum or stainless steel. * 39" Front-Operated motorized back gauge with a fine adjustment hand wheel and mechanical position readout in 0.001" increments. * 40" heavy duty squaring arm with T-slot, embedded scale and adjustable tilting stop for front gauging. * Wandering foot pedal. GENERAL - Machine can be wired for 220 or 440V, 3 phase, 60Hz - A full tank of hydraulic oil and service tools included. - One safety, operator and service manual included. - One year warranty on spare parts and labor, except tooling. Warranty shall be considered void if the machine is not used in a normal and proper manner, not properly maintained, or modified for any special use. No other warranty is either expressed or implied by HACO-ATLANTIC, Inc. or any of its representatives. For the sake of its expediency involving a minor failure, HACO-ATLANTIC, Inc. may at its option allow the user to purchase a needed part locally for which he will be reimbursed upon return of the defective part. - Installation, start up and training are included. OPTIONAL EQUIPMENT Ball transfers without table sections (16 needed for 10' shear): $70/EA Hour meter: $315.00 Stroke counter: $450.00 Length stroke control: $310.00 Protractor for angle gauging: $1,460.00 Second foot pedal in series with standard foot pedal $620.00 Extra set of blades: $2,115.00 Extra set of HCHC blades (recommended for cutting stainless): $ 2,775.00 Extra operator and service manual: $70.00 GENERAL CONDITIONS Payment Terms: 20% with order, 80% upon installation. FOB: Houston, TX